Advantages:

l Top or bottom detection

l Products can be quickly converted.

l Suitable for all kinds of bottle types

l The accuracy of that detect probe is high, up to ± 0. 05mm

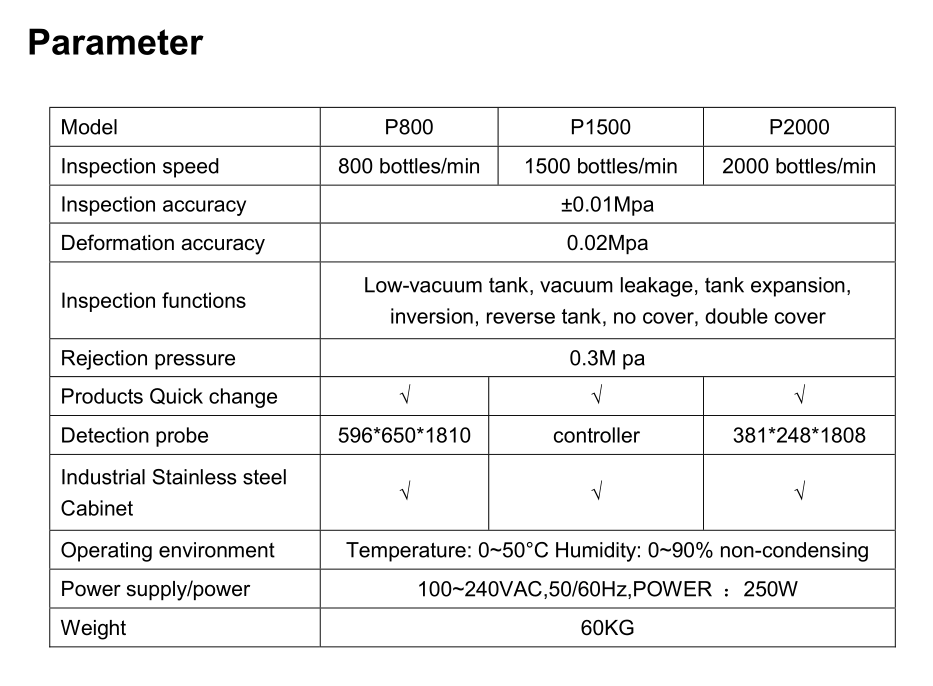

l Fast speed, up to 1500 bottles/minute (65mm bottle type calculation)

l Portable structure for easy installation and operation

l In the meantime, it is necessary to

l SUS304 Chassis Washable (IP55 Protection Design)

Vacuum inspection machine adopts sonar and deformation detection technology. When working, there is no need to touch the product, and the jar will smoothly pass through the detection area. When the container passes through the acoustic detection probe, the probe emits high-energy electromagnetic pulse to impact the bottom cover of the container in a non-contact manner, and the bottom cover emits feedback sound when impacted, and the vacuum degree of the product is judged by analyzing the echo frequency. After the curved probe detects the deformation degree of the bottle cap, it is determined whether the seal is in good condition. The equipment automatically eliminates unqualified products, the sealing is normal, and the products flow into the next production process.

It is suitable for sealing testing of glass bottles + iron caps and three-piece iron cans (tinplate cans).